Common packaging materials

2025-05-22

Single powder

1. Commonly used paper box materials have paper thicknesses ranging from 80g to 400g, with higher thicknesses requiring two sheets to be laminated.

2. The paper is glossy on one side and matte on the other, and only the glossy side can be printed.

3. It can achieve printing in various colors without any restrictions on color.

The commonly used surface treatment processes after printing are: over gluing, over UV, hot stamping, and embossing.

Pit paper

1.Compared to ordinary paper, it is straighter and has stronger load-bearing capacity.

2. Commonly used ones include single pit, double pit, and triple pit.

3. It can achieve printing in various colors, but the effect is not as good as single powder.

The commonly used surface treatment processes after printing are: over gluing, over UV, hot stamping, and embossing.

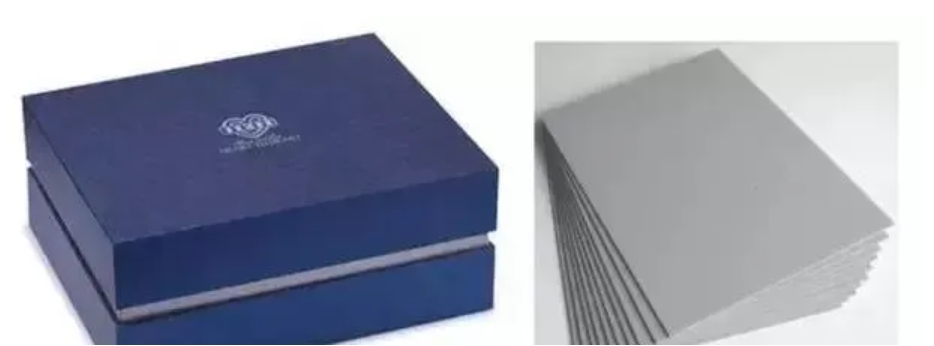

Cardboard

1. Used for making gift box structures, with a layer of single powder paper or special paper mounted on the surface.

2. Common colors include black, white, gray, and yellow.

3. There are also various grades of cardboard thickness, which can be selected according to the load-bearing requirements.

If the mounting is single powder, the process should be consistent with that of single powder paper boxes; If it is special paper, most can only be hot pressed, and some can achieve simple printing, but the printing effect is not good.

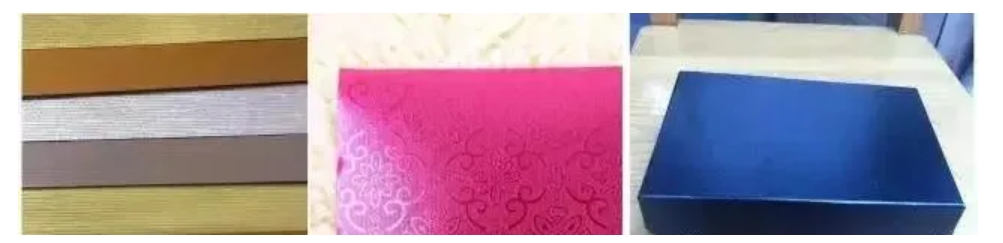

Specialty paper

1. There are many types of specialty paper, but here we only mention the ones we use in packaging materials: embossed paper, patterned paper, pearl patterned paper, metallic patterned paper, gold paper, etc.

2.These papers can be specially processed to enhance the texture and grade of the packaging. Embossing and embossing cannot be printed, only surface hot stamping can be used. Star color, gold color, etc. can be printed in four colors.

Gold and silver cardboard

1. Use UV transfer printing technology to apply a layer of UV oil on the surface of the paper through a rubber blanket, and then transfer the light column film or specific pattern onto the printing paper through a roller, creating a light column on the surface of the paper with the effect of

laser paper.

2. It can only be printed with UV machines, and various pattern effects can be achieved, which is more textured than ordinary paper and has different types of gloss. But the cost is relatively high.