Common packaging techniques

2025-05-20

1、 Four-color printing

1.1. The so-called four-color refers to four inks: cyan (C), magenta (M), yellow (Y), and black (K). All colors can be mixed with these four inks to achieve color graphics and text.

1.2. The most common and ordinary printing method produces different effects on different substrates.

2、 Spot color printing

2.1. Spot color printing refers to the use of a special ink to print a color that is brighter than a mixture of four colors. The commonly used ones are specialized gold and specialized silver.

2.2. There are many spot colors, refer to the Pantone color chart, spot colors cannot achieve gradient printing, and if necessary, four-color printing can be added.

3、 Gloss adhesive

3.1After printing, a transparent plastic film is hot pressed onto the surface of the printed material to protect and increase its gloss, resulting in a shiny surface as shown in the following figure

3.2 The most basic process for surface treatment of paper boxes. There is also varnish, but glue can enhance the hardness and tensile properties of paper.

4、 Covered with matte film

4.1After printing, a transparent plastic film is hot pressed onto the surface of the printed product to protect and increase its gloss. The surface is matte, as shown in the following figure.

4.2. The most basic process for surface treatment of paper boxes is similar to using varnish, but using glue can enhance the hardness and tensile properties of the paper.

5 U V

5.1. The highlighted areas of printed materials need to be partially polished to enhance the three-dimensional effect of the local patterns.

5.2. When printed with matte adhesive technology, there is no effect when using glossy adhesive.

6、 Hot stamping

6.1. Hot stamping is the use of the principle of hot press transfer to transfer the aluminum layer in electroplated aluminum to the surface of the substrate to form a special metallic luster effect.

6.2. Printing materials come in various colors such as gold, silver, red, green, blue, etc., but hot stamping can only be monochrome. There are many types of colors, but not all colors are available in the market.

7、 Strike convex

7.1. Use a set of concave and convex templates corresponding to the yin and yang of the graphic and text, place the substrate between them, and press out the relief shaped concave and convex graphic and text by applying a large pressure.

7.2. Various thicknesses of paper are acceptable, cardboard cannot be embossed.

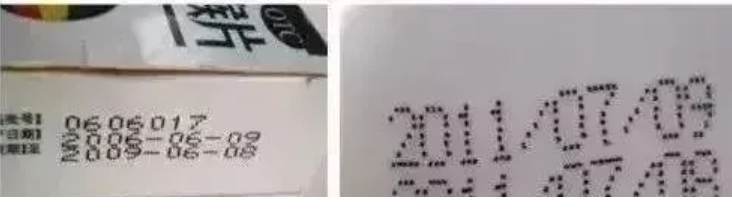

8、 Spray code

8.1The process of using a coding machine to print identification (production date, shelf life, batch number, company logo, etc.) on products.

8.2. It can print simple character patterns with greater flexibility.

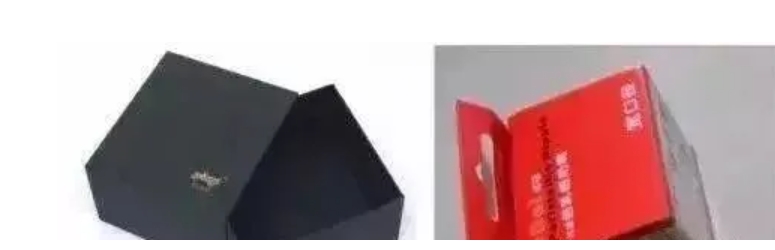

9、 Vacuum forming

9.1. Blister is a transparent material, mainly made of PVC, PE, or PET.

9.2. It can directly replace paper to make boxes, or be used in conjunction with business card printing.

9.3. It can be used to fix products inside the packaging, which is called vacuum forming.

9.4. It can be silk screened, printed, or hot pressed.

9.5. It can be printed on the machine, but the printing cost is relatively high, and small-scale production usually only uses silk screen printing.

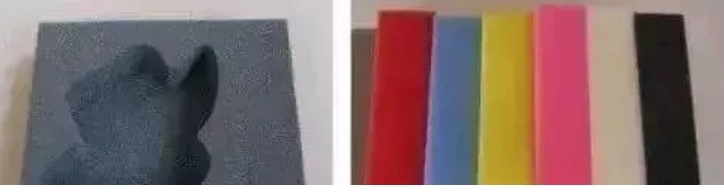

10、 EVA

10.1The chemical name is ethylene vinyl acetate copolymer, and the finished products made from it have the characteristics of good softness, shock resistance, slip resistance, and strong compression resistance.

10.2. Used in packaging and interior to secure and protect products.

10.3. There are multiple colors to choose from, and the surface can be processed with flocking or velvet wrapping techniques to enhance the visual effect.

11、 Sponge

11.1. It is a porous material with excellent elasticity. The density and elasticity of pores vary.

11.2. Used in packaging and interior to secure and protect products.

11.3. There are multiple colors to choose from, usually used directly without overlapping craftsmanship.